Why Choose Hex Technology?

Because you deserve certainty.

You deserve to know every flange on your site was assembled the right way, with the right process, by the right people.

And you should feel confident each person putting hands on fixed equipment has the knowledge and ability to do their job well.

What We Do for You

Hex Technology delivers certainty in today’s unpredictable world by helping sites develop safer, more reliable bolting programs.

We help protect your assemblers.

We save you time and money. (As in millions.)

We achieve this through a system that ensures that your staff understands and can act on the industry’s best practices.

It’s a system for continuous progress – one that’s informed by research and refined by decades of directly working with maintenance and turnaround crews on the industry’s front lines.

And every step of the way, we keep it real and relatable. While our staff serves in leadership roles committees overseeing our industry, like ASME PCC-1, we also can explain the connection between gasket stress and nachos. (<-It’s a thing, trust us.)

The result: Training that wins attention, earns buy-in, and facilitates lasting improvement.

Trusted By

How We Deliver

We offer you a scalable solution for leak prevention through better assembly.

Your site can achieve higher quality and consistency in flange makeup because of our unique approach.

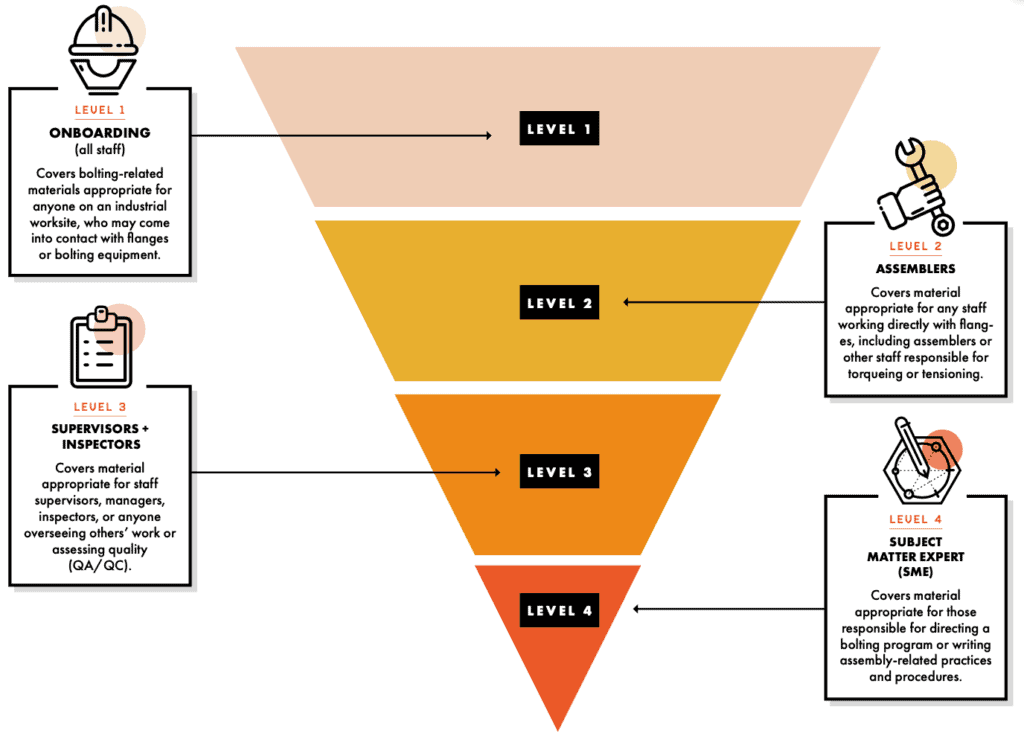

You can liken the approach to an inverted pyramid.

This approach recognizes that the moment an assembler puts their hands on a flange what determines how the equipment will perform throughout its lifespan.

Everything else – from the site procedures to craft supervisors to inspectors – exists to ensure that moment is flawless.

Assemblers must understand their procedures, and know when to raise their hand. Supervisors and inspectors must discern good from bad, and be able to spot signs something is amiss before it becomes a problem. And the program can’t ride on just handful of engineers or subject matter experts. A wider base (of people who truly understand bolting) makes for stronger support.

What You Get

When you partner with Hex, you put your craft personnel on a clear path for continuous progress.

Our method is informed by research data, work with leading industry organizations (including ASME), and direct boots-on-the-ground training with crews around the globe.

The result is a process that accounts for every stakeholder in bolted flange joint assembly – and provides them with exactly what they need to perform at a high level.

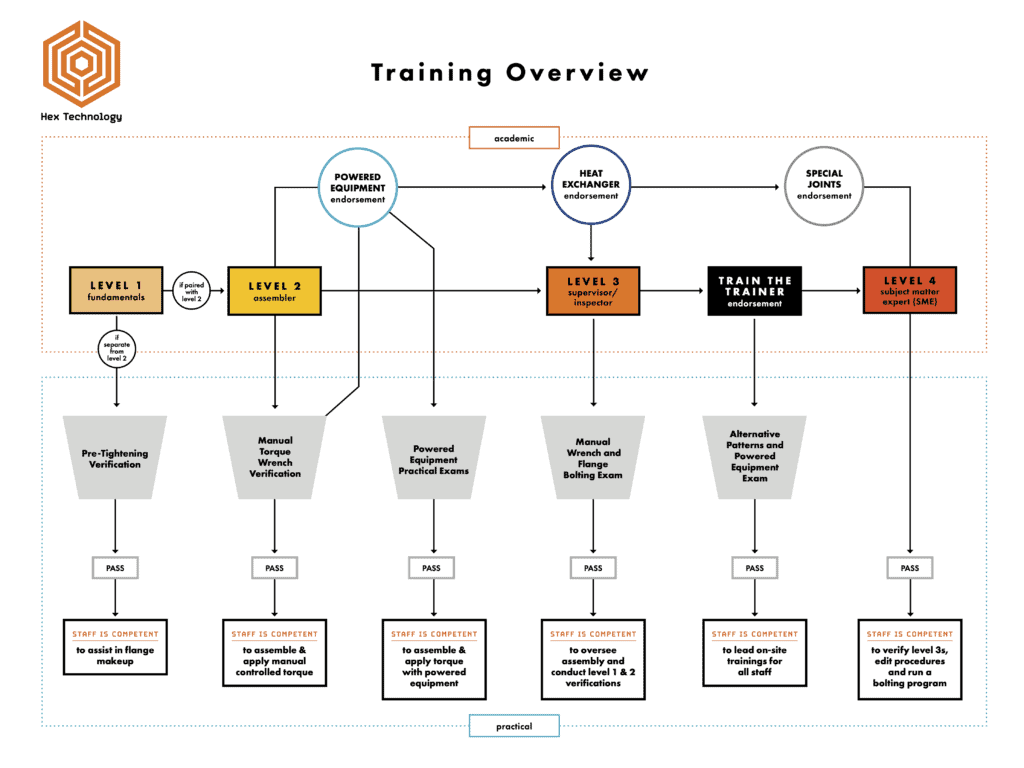

This system encompasses both the fundamental knowledge (academic) side of assembly and the hands-on practical skills needed to perform.

Our course materials are designed so that your staff will be able to easily follow and quickly understand. Each level of your organization will find classes designed to meet the needs of their unique role.

Our Commitment to You

When you choose Hex Technology, you’re choosing a training solution that is…

- Independent – Improving your site’s performance is all we do. Training is our product, not a loss leader for selling you other products. Your team is our sole focus.

- Unbiased – To stay on top of the marketplace of available solutions, we maintain relationships with multiple tool, gasket, lubricant and other component manufacturers, but are beholden to none. Any recommendations we make are based on need and effectiveness.

- Experienced – Our teams have trained and written procedures for sites across the industry and around the globe. We know how it’s done at the biggest (and smallest) sites and companies.

- Collaborative – We regularly partner with End Users, manufacturers and laboratories for new studies. We’re always searching for answers and sharing information for better solutions.

- Research-backed – Our practices aren’t based on anything but data. There are no unfounded theories here. We bust myths, challenge assumptions, and verify with tests.

- Accessible – Your crews can access course materials 24/7/365 through our online learning platform. Available on any device, in any location. All certificates remain on file and readily accessible by staff or management.

- Responsive – You can expect an answer to any question, or a response from our staff, within 24 hours during business days.

Protect your front line. Boost your bottom line.

Set up a discovery call with our staff today.

We’ll help you assess areas of need and identify potential solutions.

Find out why we’re the global leader in bolted flange joint assembly training.