Torque Tool Calibration and Verification

Hex Technology conducted a torque tool calibration and verification study with a small refinery. In this study, we analyzed the different types of torque tools…

Hex Technology conducted a torque tool calibration and verification study with a small refinery. In this study, we analyzed the different types of torque tools…

Corrugated Metal Gaskets (CMGs) are gaskets that we see a lot in heat exchangers where we see plenty of radial shear. Typically, we suggest the use of…

Galvanized vs other corrosion resistance coatings. We talk about the difference between galvanized and black oxide coatings. Click here to read about PTFE…

Discussing the effectiveness and necessity of relaxation pass and start-up re-torque procedure according to industry research over relaxation behavior. …

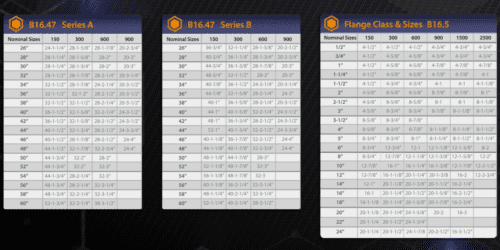

Including Pipe Flanges, RTJ’s, Raised Face, and Custom Flanges Different flange types and sizes require specific stud bolt dimensions. This article will…

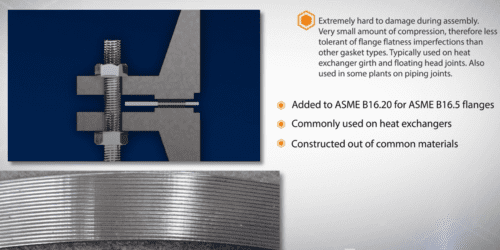

Kammprofile Gaskets (also known as grooved metal gaskets or spelled as camprofile gaskets) are our best friends in the heat exchanger world due to their…

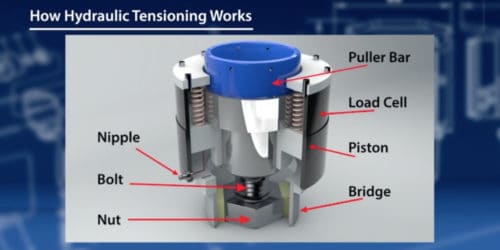

Take these factors into consideration before using hydraulic bolt tensioning. While the practice is highly accurate, it isn’t always best.