Watch What Happens When You Take a Bolt Past Yield

Let’s start with the big myth about steel bolts and yield strength.

What we often hear from people in the field is: “Well, if the bolt is broken, it’s been put into yield.”

That’s not actually true.

The video below shows you what happens when a bolt goes past its yield point.

Note how you can’t tell there’s a problem with the threaded fastener just by looking. It’s easy to tighten the bolt past the yield point and not know you are past permanent deformation.

And notice how even after the steel bolt has surpassed minimum tensile strength, a nut will still run up and down the threads just fine.

What is Bolt Yield?

A bolt’s yield point is where the stress placed on a fastener surpasses its ability to recover its elasticity.

Remember: Steel may seem firm, but it’s actually an elastic material. That means when you fasten a bolt, you are actually stretching the material.

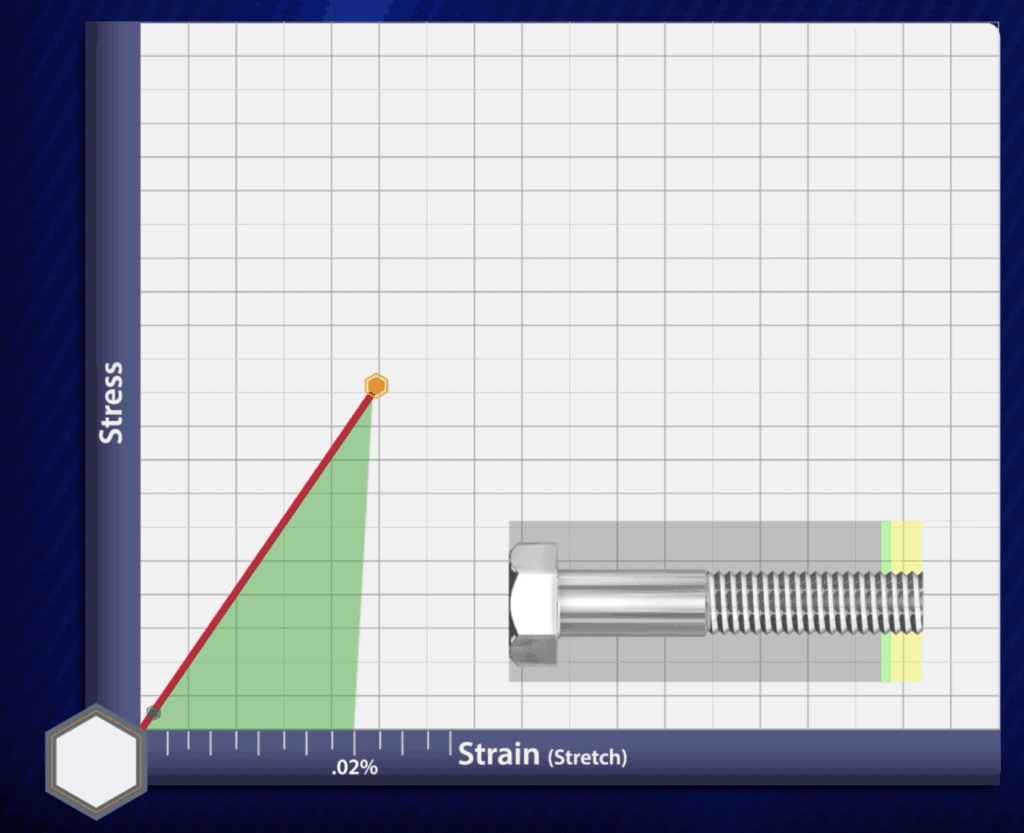

The stress applied to a bolt is known as “tensile stress” or “preload.” In the graph below, you’ll see stress graphed on the y-axis, while the amount of stretch on the fastener is shown on the x-axis.

The preload added to the threaded fastener remains pretty linear — until you reach the yield point. This is known as the proof load or proof stress, and it’s the maximum load a fastener can take before it hits permanent deformation (also known as plastic deformation).

When a fastener reaches a point of plastic deformation, in simple terms, this means the fastener won’t go back to its original shape. (Technically, this means the bolt won’t go back to being within .02% of its original shape.)

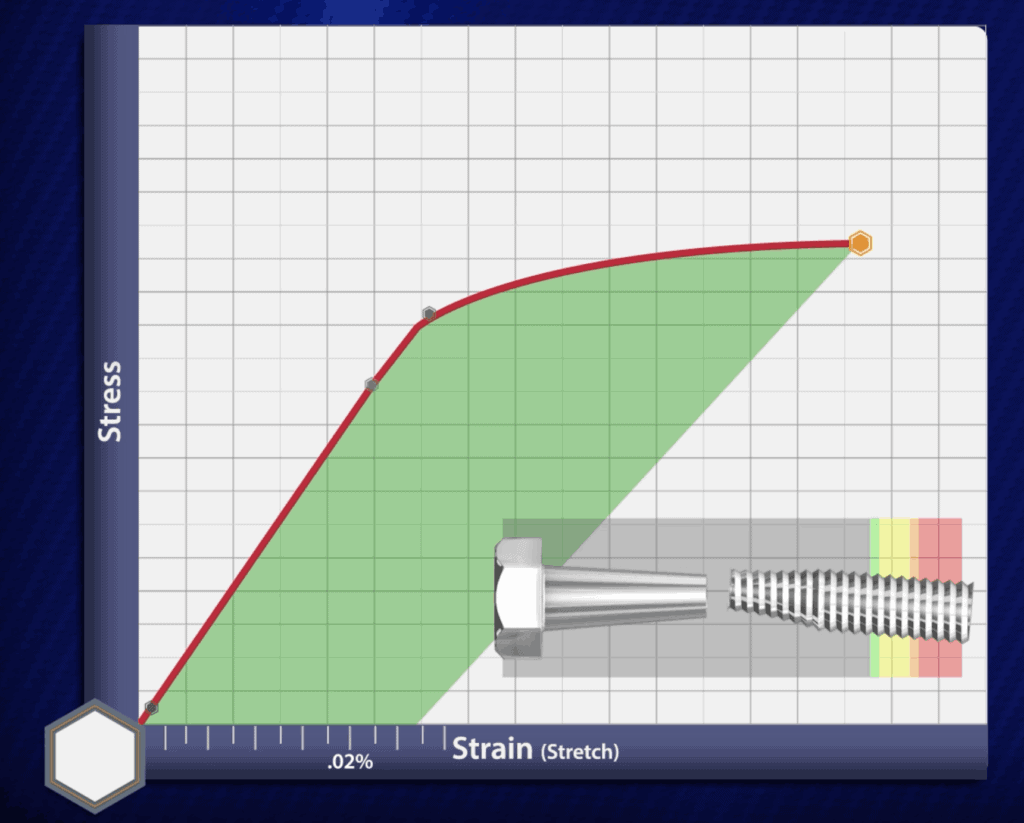

If you were to continue applying load and stretching the fastener, the stress-strain curve takes a bad downward path:

If we keep stretching the fastener until we hit the ultimate tensile strength (also called maximum load). This is when a bolt starts “necking” and, eventually, breaks.

But long before the fastener breaks, since the curve past the yield point is not linear, we do not know the preload of the stud. Therefore can’t predict the clamping force the fastener is placing on the flange.

Once we understand this we can address the property classes of each common material found in the industrial industry.

NOTE: This article will concentrate on ASTM A193 & ASTM A320 type of fasteners. It does not address metric bolts, SAE J429 (medium carbon alloy steel bolts), or ASTM A449 (medium carbon steel bolts).

What is the yield strength of common fasteners?

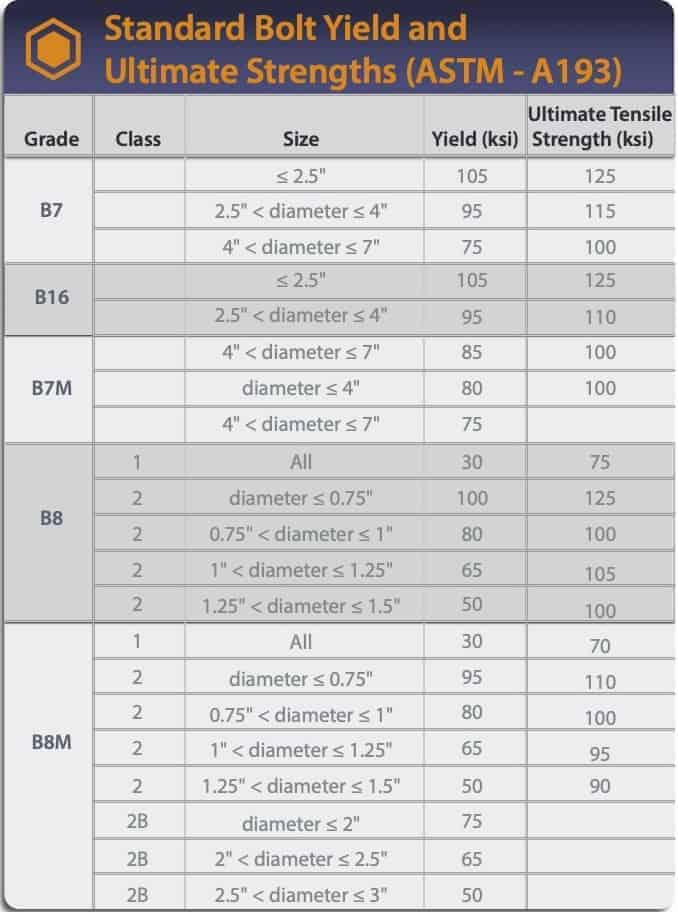

Different materials in steel bolts, and the different stress areas of those bolts, play a crucial role in the strength requirements for their bolting applications.

The material differences are pretty self-explanatory. But the stress areas have to deal with how the steel bolt is quenched during manufacturing. Since there is more material in larger bolts, it is harder to quench them. Therefore their yield strength is effected.

Below is a chart of the yield strengths and ultimate tensile strengths for common ASTM-193 bolt grades found in petrochemical bolting applications.

Should You Re-use Bolts?

As we’ve shown you in this article, most people don’t really know when they’ve actually put a bolt into yield. So the logical question becomes: “When can we re-use studs?”

Well, ASME PCC-1 states that when using controlled bolting methods such as torque or tension, the use of new bolts up to 1-⅛ inch diameter is recommended.

What does that mean? If you’re going to use controlled bolt load techniques like clicker wrenches, hydraulic torque wrenches or even tensioning, you should probably replace the bolts if they’re 1-⅛ inch diameter and below, because the cost of refurbishing those bolts is higher than replacing them.

Meanwhile, the industry in general has been moving to replacing fasteners when controlled bolt load (torque or tensioning) is used to get clamping force on a flange.

Hex Technology has heard how replacing all studs is expensive. But again, note that the recommendation is for times when controlled bolting is being used.

Why? Because while your torque value and preload are almost the same for new and used bolts, there are many variables that the fastener will encounter during operation.

These are hard to quantify, therefore it is easier, safer and less costly to replace the fasteners than to do an engineered assessment to determine if they need to be replaced in most cases.

RELATED:

Beyond ASME PCC-1: What Today’s Bolting Professionals Need to Know

A Guide to Bolt Lubricant and Torque

Join Industry Leaders!

Subscribe to Hex Technology today and we’ll give you $700 in bolting courses, FREE. Your path to a safer, more reliable, more profitable site starts here.