Correct Fastener Preload: What We’re Trying to Achieve

Before we dive into the comparison of bolt tensioning vs. torquing, let’s remind ourselves what we’re trying to achieve when we use either.

The ultimate goal in bolting is to achieve the correct fastener preload (also known as bolt load or axial load). Applied appropriately to a gasketed bolted connection, the bolt load creates clamping force (or “clamp load”) on the gasket. The result: A reliable, leak-free seal.

Bolt torque and bolt tensioning are both legitimate ways to seal a joint. Bolt torquing exerts a rotational force on the fastener, while bolt tensioning involves stretching a fastener with what looks like a hydraulic load cell.

Which is the “best method”?

Well, a torque wrench sales guy would tell you torquing is the way to go. A tensioner sales or service guy would tell you tensioning is the best way to do things. But really, which is “best” is a loaded question, and depends on…

- Joint criticality

- Joint component accessibility

- Available equipment

- Expertise of personnel

…and more.

In this article, we’ll provide definitions of for bolt torquing and bolt tensioning, explain some pro’s and con’s for each, and offer guidelines for the use of each.

NOTE: For the sake of everyone’s time, we’re not going to talk about tension indicators, hydraulic bolts, or direct tension indicating washers.

What is Bolt Torquing?

Torquing is the most commonly used way to achieve fastener preload with bolted joints. Torquing produces this load through rotational force on a nut or bolt head. This torque is usually measured in foot-pounds (ft-lbs.) or Newton-meters (Nm).

Whether the bolt torque is achieved through the use of a manual “clicker” torque wrench, pistol grip torque wrench, or a hydraulic torque wrench, it is the most simple method of achieving axial load.

The big advantage to torquing is that is typically more cost-effective than tensioning.

However, the skill levels and training of those who use the torque tools equipment are determinants of how successful and accurate torque tightening will be.

Additionally, to achieve correct torque-tension relationship, the K-factor is critical. (And note, K-factor is NOT the same thing as coefficient of friction.) A proper K-factor is critical for understanding what applied torque value you will need.

You also need to take into account friction on bearing surfaces, the bolt diameter, and other variables, which are best examined through experimentation.

What is Bolt Tensioning?

As mentioned above, bolt or stud tensioning produces axial load by pulling up on a fastener with what looks like a hydraulic load cell.

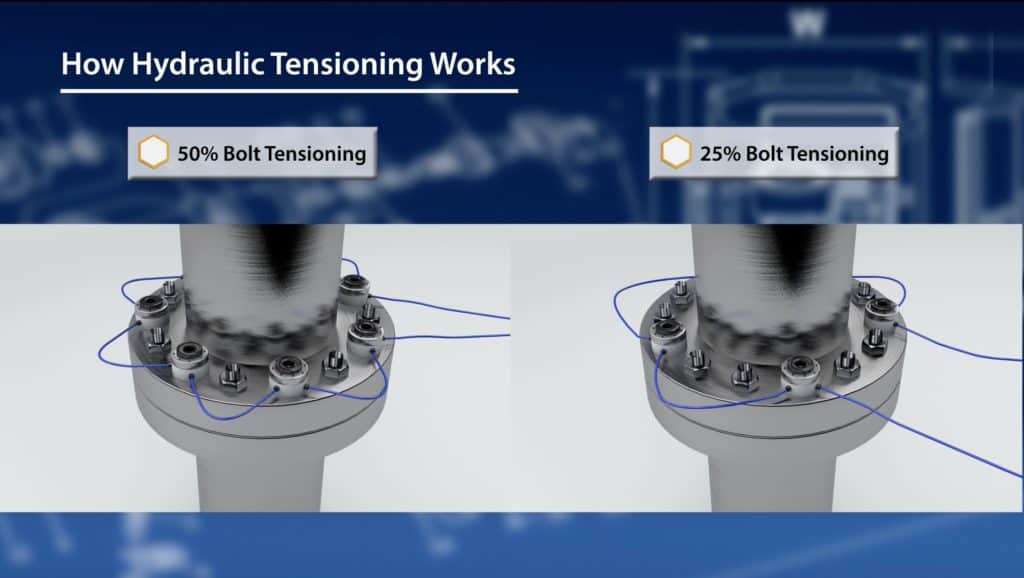

To achieve the targeted bolt load, you need to know the area of the tensioner and the amount of force on the fastener, and then adjust the amount of hydraulic pressure.

Hydraulic tensioning began in the 1970s, and in the 50+ years since, tensioning has become more common on specific applications, especially high-pressure flanges with large bolt diameters or critical joints across many industries, including oil and gas, wind, subsea, and power generation.

Because tensioning does not place a twisting force on the fastener as applied torque does, we see tensioners used with long threaded fasteners and on rotating equipment such as reciprocating rods.

Another good use of tensioning is large bolt diameters. On large bolt diameters, tensioning will save you time compared to using hydraulic torque wrenches.

Bolt Torquing vs. Tensioning: What’s More Accurate?

Tensioning is more precise — but there are ways torquing can narrow the gap, if it’s applied correctly.

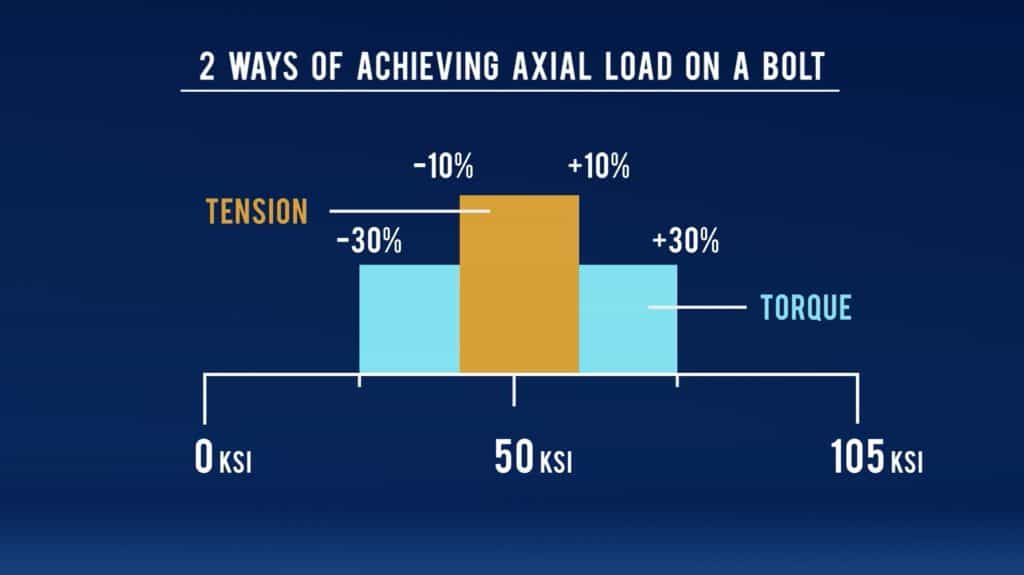

Torque tools are generally considered accurate within plus or minus 30%. That means if your target was 50 KSI of load, you could see anywhere between 35 KSI and 65 KSI bolt load on your fasteners, and you’d be okay with that.

(The differences in bolt load from fastener-to fastener in flange is known as “bolt scatter.” The lower the bolt scatter, the more consistent the flange assembly.)

With tensioning, you’re typically going to see +/- 10% accuracy. That means your bolt scatter will be lower. If the target was 50 KSI, you’d see values between 45-55 KSI.

However, there are some important caveats to note here.

First, tensioning is more expensive and more complicated than torquing. So you will need people who have been properly trained in order to properly apply stud tensioning. Torquing, on the other hand, is fairly simple and torque wrenches are readily available in any industrial plant.

Second, torquing can be significantly more accurate than 30% when performed by an appropriately trained assembler, with proper lubrication and with calculations that include a proper (experimentally determined) K-factor. It’s not uncommon for well-trained craft assemblers to achieve +/- 15% accuracy or better with torquing.

Related:

The Stud Guide: B7s, B16s and Other Common Bolts

Torque Calibration in the Lab and the Field

Join Industry Leaders!

Subscribe to Hex Technology today and we’ll give you $700 in bolting courses, FREE. Your path to a safer, more reliable, more profitable site starts here.