Hydraulic torque wrenches are a staple in the fastening of industrial bolting applications.

These wrenches are necessary to achieve high torque outputs (greater than 600 ft. lbs.) on a fastener. Manual clicker wrenches capable of reaching 1000 ft. lbs. do exist, but they are brutally difficult to use. Power tools are easier on the assembler and lead to better accuracy and repeatability.

Since hydraulic tools have a high torque output, they need to be powered by a hydraulic pump. This pump or “power pack” relays high-pressure hydraulic force through a hydraulic hose in order to produce the target torque output.

If calibrated correctly, the hydraulic pump will allow the user to change the torque setting accurately. Hydraulic pumps can be powered by either pneumatic (air-driven) or electric power.

Hydraulic torque tools can have a minimum torque of 100 ft. lbs. and a maximum torque of 120,000 ft. lbs. Both the minimum and maximum torque depend on the capacity and size of the hydraulic equipment. Hydraulic torque wrenches are especially useful on large bolts (1-inch diameter or greater). In the sections below, we’ll explain how hydraulic torque wrenches work, starting with the pumps that power them and working outward to the tools themselves.

Hydraulic Pump (Or “Power Pack”): Where it Begins

A standard pump can generate up to 10,000 PSI, and allow you to adjust the torque setting on the hydraulic wrench. Most pumps work with all major tool brands.

Pumps are either electric or air-driven, though you’ll typically see pneumatic hydraulic pumps used in hydrocarbon processing. Using an electric pump for some bolting applications may require you to get a “Hot Work Permit,” due to the electricity.

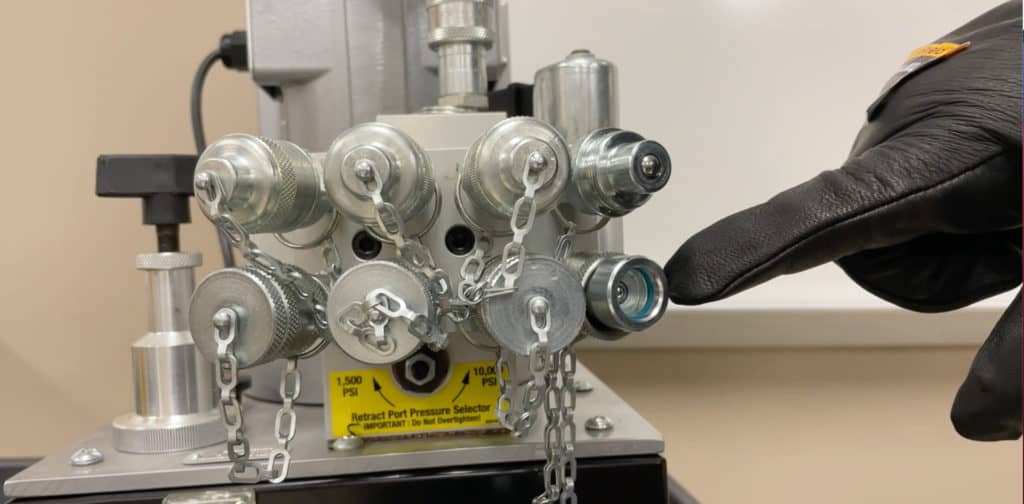

For all hydraulic torque wrenches, a hose connects the hydraulic pump to the hydraulic wrench itself. The hose connections (or couplers) are set up so that you cannot hook up the hose incorrectly — the male/female attachments require the right match in order to connect (see photo above). Therefore, connecting the hose to the pump is intuitive and easy.

Hydraulic Hose: Keep an Eye on This Connection

After you power up the pump, you’ll adjust the pressure to match the correlated target torque value on the calibration sheet. The hose attached to the hydraulic tool on what is called the uni-swivel. Logically, the uni-swivel can handle up to 10,000 PSI.

IMPORTANT NOTE: Hydraulic hoses SHALL (i.e. must) be rated for a 4:1 hydraulic pressure, which means rated for 40,000 psi.

There are setting to advance or retract. Advance will fill the piston with hydraulic fluid, which then advances the piston to push on the drive pawls. The drive pawls rotate, which causes the nut to rotate.

ANOTHER IMPORTANT NOTE: Carefully inspect a hydraulic hose for damage or holes before use. If pressurized liquid were to escape through a hole, the stream that would result would be capable of causing severe injury (think: lost fingers or deep cuts).

Square Drive Bolting Tools: Best for Breakouts

The square drive bolting tool is the most common hydraulic torque wrench in industrial bolting. Square drive sizes include ½”, ¾ “, 1″, 1 ½”, 2 ½”. Size dictates the maximum torque output that these tools can generate.

Experience shows square drives are best suited for breaking out, as square drives are more robust and have fewer moving parts than low profile wrenches, making them less prone to breakage.

A square drive tool’s reaction arm places it further away from the flange (due to the impact socket and square drive), therefore square drives are more difficult to use for assembly than a low profile hydraulic torque wrench.

Low Profile Bolting Tools: An Assembler Favorite

Low profile hydraulic wrenches consist of two parts: A powerhead and a link. The link makes low profiles unique because each set of links fit over a specific size of nut. You can change the link by pulling the link pin, then sticking on a differently sized link.

Low profile wrenches go upward from 2,000 ft. lbs. to 4000, 8000, 16,000, and so on. You need a link for every wrench of that size, meaning you might need multiple links for a 2,000 ft. lb. version, multiple links for the 4,000 ft. lb. version, and so on. Links for different model tools are not interchangeable.

As you might guess from the name, Low Profiles are absolutely awesome when dealing with low clearance issues. The reaction point for a low profile is right up against the next adjacent nut. The low-profile wrench may be the assembler’s favorite hydraulic tool because it is easier to use than a square drive.

Hydraulic Torque Wrench Safety

With the high-pressure fluid and extremely powerful mechanical reaction arms, there is great potential for injury with improper hydraulic equipment wrench use. Hex Technology recommends any site that uses hydraulic tools first undergo safe use and operation training.

Always depressurize the hydraulic hose prior to use. Store hydraulic hoses in a circle wrapped end to end, and do not screw the ends on one side together. As mentioned above, if you see any steel braiding bins, cracks, burns or kinks, do not use that hose.

The other major safety concern for all hydraulic torque wrenches is pinch points resulting from reaction points. You know enough physics to know that for every action, there is an equal and opposite reaction. In bolting, this means that if an assembler is applying 1000 ft. lbs. to a bolt, the reaction arm is applying that same amount of force to the adjacent nut. You do not want any part of your body caught between those two pieces of metal.

There are two major types of hydraulic tool designs out there: Those with holding pawls and those without holding pawls. A holding pawl allows the tool to ratchet without using the “wind up” on the fastener. The holding pawl will get bound up on the fastener at some point, and while the tool will ratchet, it will be hard to take off the flange.

When this happens: DO NOT take a hammer to the tool. Instead, power up the tool through the hydraulic pump then depress the holding pawl, and the hydraulic tool will release.

Hydraulic Torque Wrench Maintenance

An important aspect of hydraulic torque wrenches maintenance are watching the seals. Often, these seals are the first thing to break. If you see oil in your hydraulic pump that looks milky, full of water, dirt, or grime, those impurities will travel along with the hydraulic fluid through your tool and eat away at your seals.

The second maintenance factor to mind are the hydraulic hoses. The couplers on hoses regularly get grime and gunk and everything else put through and onto them. Then people will place channel locks or pipe wrenches onto the couplers to try and tighten them. Please clean the fittings with each use so you don’t have to do this, as channel locks will damage and eventually ruin the couplers.

If you have to replace a fitting, please make sure to follow the hydraulic hose manufacturer’s requirements.

The hydraulic pump doesn’t usually require in-field maintenance, but may require some troubleshooting. Air-driven hydraulic pumps will have an FLR, or “filter lubricator regulator.” When you hook up air to your hydraulic pump, there’s a little nozzle on the bottom of the filter. Dump all the water and gunk and grime out before you start running your tool. Because if that gunk and grime go through your FLR, it will travel through the hose into your air motor, and tear up the motor.

You’ll see the FLR has a little sight glass that allows you to see the oil going in. Make sure the oiler is putting in one drip of oil every 10 seconds. This oil lubricates the air motor, ensuring it doesn’t bind. Having the oil drip more frequently will lead to oil exhaust on the handle, but if the tool doesn’t oil frequently enough, it will bind up the pump and you’ll eventually have to swap the pump out.

It is our recommendation that you reach out to the torque wrench manufacturer. They normally do a safe use and operation and troubleshooting course on their tools, as each different manufacturing and each different model of tool has its own quirks and purposes for each individual part.

After any maintenance on a hydraulic torque wrench, you have to recalibrate the tool. It’s necessary to re-grease both the drive pawls and the side plates so the pawl can move back-and-forth easily against the side plate, doesn’t get bound up, and doesn’t gall.

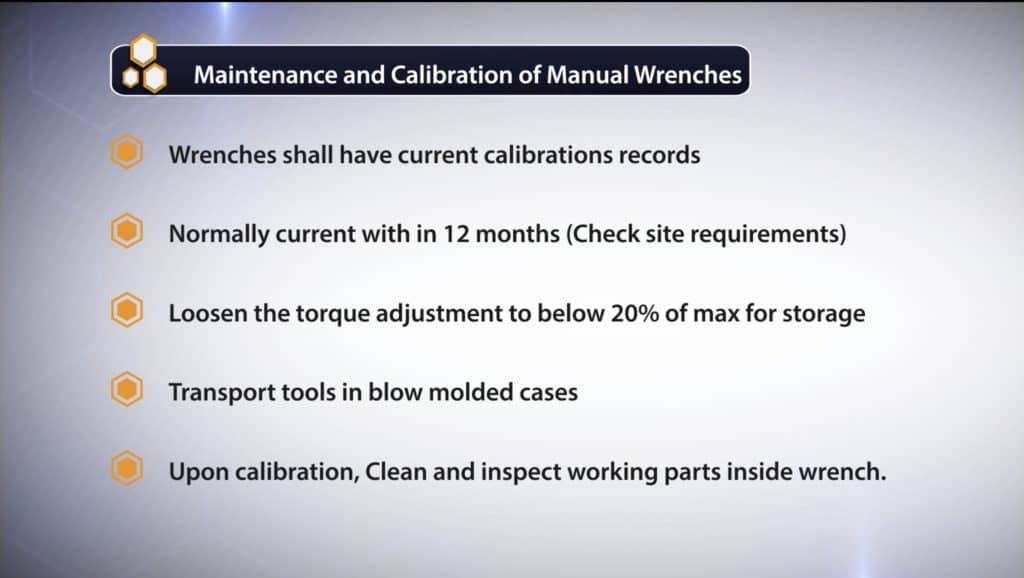

Calibration: When and what’s required

There are two elements of a hydraulic torque wrench that need to be calibrated:

- The actual wrench itself.

- The gauge on the hydraulic pump.

Both of these components should be calibrated at least once every 12 months. Once the tool is calibrated, a new torque chart needs to be generated. The updated chart is what your crews will need to use with that tool from that point on. Always check the serial number and date to ensure you have the correct calibration chart for that tool.

If you have questions or your site needs training on the use of hydraulic torque wrenches, contact Hex Technology.

Join Industry Leaders!

Subscribe to Hex Technology today and we’ll give you $700 in bolting courses, FREE. Your path to a safer, more reliable, more profitable site starts here.